An Inline air filter is installed in air purification systems and equipment to protect both the system, and the people relying on them, from damage caused by contaminants, harmful particles, and debris that passes through them. Any contaminants such as pollen, dust, or even viruses may be captured once they enter an air purification system by these filters. Read More…

Duraflow Industries is the premier aftermarket and OEM supplier of various filtration products. We feature a complete line of filters for applications such as air scrubbers, absorption of thousands of organic compounds, drinking water filtration, and waste water abatement. Our just-in-time production techniques allow us to maintain production flexibility and meet fast turnaround times. From...

For more than 25 years, RoboVent's focus has been on the delivery of clean air and healthy environments in manufacturing facilities. This has earned us the leading position in the collection and filtering of airborne contaminants generated by metalworking and other industrial processes. We are passionate about providing clean air solutions to the industry, and this dedication to the cause brings...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

At Filpro Corp., we specialize in designing and manufacturing high-performance air filters tailored to meet the diverse needs of our clients. Our commitment to excellence drives us to produce air filters that ensure superior air quality and system efficiency across various applications. We offer a comprehensive range of air filtration solutions, from residential and commercial HVAC systems to...

MCR inventories a large stock of Cleanroom Fan Powered and Ducted Air Filters. The Mac 10 FFU is known for being the quietest filter available and has been tested below 5O dBA with a rated flow of 90 FPM. Its modular design fits conveniently into 2`x4` to 2x2 T-Bar drop ceilings, and with a low profile of less than 13" it permits installation into tight ceiling spaces. Contact our company today!

More Inline Filter Manufacturers

These filters are suitable for applications that require constant flow capabilities. Inline air filters are available in various sizes, ranging from miniature to large sizes.

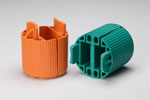

Construction of an Inline Air Filter -

An inline air filter is made of the following components:

- The Case:

The case of the inline air filter is made of plastic. Pallets of raw material such as polystyrene, polyvinyl chloride, polyethylene, or polypropylene are injected into the molds to form the case of these filters.

- An Electric Fan:

An electric fan is attached to the case in these filters with the help of many screws. The electric fan is used to pull the air through the purifier.

- Filters:

Filtersare attached to both sides of the case with inline filters. The filters extract the contaminants from the air purification system and help clean the air instantly.

- Control Switches:

Control switches are also an important part of inline air filters which are used to control fan speed and also to power on/off the purifier.

Materials Used for an Inline Air Filter -

An inline air filter can be made of many different types of materials such as paper, fiberglass, foam, carbon, aluminum, steel, and plastic. The material of the filter depends on its application and the type of contaminants that it is being used to screen out.

Working of an Inline Air Filter -

A filter is called “inline” if it can be installed anywhere in a compressed air piping system. Inline filters work by trapping solid particles from the compressed air. These particles are contaminants that are captured by these filters by a straining process. The main components and the flow process of air filter is as follows:

- Inlet (where air enters the filer)

- Air Path (the flow of air through the filtration system)

- Filter Baffle (used to direct and restrain the flow of air and contaminants)

- Filter Discharge (where the filter is removed)

- Filter Element (the filter material and/or the filter itself)

- Filter Bowl (places where the water and debris that have been removed are stored)

- Filter Quiet Zone (a zone at the bottom of the filter bowl where the contaminants are collected)

- Drain (where contaminants are removed)

The air enters into the filter using the inlet and is processed through these components. The first step of the filtration process is that the compressed air is passed from the mesh filter. Due to this, a clumping effect is created which traps the larger particles in the filter and converts any liquid into bigger droplets.

Those condensed liquid particles are then moved to the separation chamber. This is the honeycomb-like structure present in the inline filter that allows these condensed particles to get attached and settled on the filter’s pads. It helps in the movement of droplets to the drain. In the end, these droplets are drained through the drain valves. Inline air filters remove bigger particles or contaminants, oil, and water droplets.

Types of Inline Air Filters -

The compressor air filtration system uses a variety of filters and each type has unique characteristics for purifying the air.

Particulate Filters -

Particulates are a mix of extremely small solid particles and liquid droplets. Particulate filters are used to eliminate them from the air by trapping particles that come from the adsorption dryer (used to dry moist air) into the filter material.

Activated Carbon Filters -

Activated carbon filters are used in certain environments like petroleum refineries to clean the compressed air of oil droplets. The surface active adsorption of these filters bond with odors, and oils which helps in easy removal.

Coalescing Filters -

A coalescing filter is efficient in removing water and aerosols from the compressed air. The smaller droplets are caught easily into these filters, and are converted into bigger droplets. These droplets are then removed from the filter, and are prevented from re-entering through its re-entrainment barrier. It is considered an efficient filter to use for stopping various offenders since it can trap oil, water droplets as well as particulates.

Cold Coalescing Filters -

These filters are operated at low temperatures and are best to use for moisture removal from the air.

Compressed Intake Filters -

Compressed intake filters are the first defense against contaminants. These filters can trap the contaminants up to 0.3 microns and also helps in removal of chemical contaminants from the air.

High-Efficiency Filters -

These are highly efficient filters that can remove particulate matter up to 0.01 microns.

Benefits of Inline Filters -

Inline filters are widely used in many industries such as military, energy, food and beverages, petrochemical, pharmaceutical, and life sciences industries. Inline filters are beneficial to purify the air. These are efficient in trapping particulate matter that can cause many air-borne diseases or contaminate materials and products. Inline filters are to be replaced and cleaned from time to time for better performance and protection.

Choosing the Right Inline Filter Supplier

To make sure you have the most productive outcome when purchasing Inline Filters from an Inline Filter Company, it is important to compare at least 5 or 6 Suppliers using our list of Inline Filter suppliers. Each Inline Filter Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Inline Filter company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Inline Filter companies with the same quote.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services