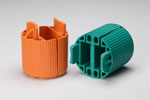

Foam filters are air cleaner filters that use polyurethane foam elements as the filtering material to trap unwanted air contaminants and particulates. Foam filters are made up of tiny interlocking cells that prevent the passage of dirt particles and distribute these throughout the entire volume of the foam. Foam materials are used in many performance air filters for engines on appliances such as lawnmowers, power tools and other power equipment. Read More…

Duraflow Industries is the premier aftermarket and OEM supplier of various filtration products. We feature a complete line of filters for applications such as air scrubbers, absorption of thousands of organic compounds, drinking water filtration, and waste water abatement. Our just-in-time production techniques allow us to maintain production flexibility and meet fast turnaround times. From...

For more than 25 years, RoboVent's focus has been on the delivery of clean air and healthy environments in manufacturing facilities. This has earned us the leading position in the collection and filtering of airborne contaminants generated by metalworking and other industrial processes. We are passionate about providing clean air solutions to the industry, and this dedication to the cause brings...

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Hengst Air Filtration, we are driven by a passion for clean air and advanced filtration solutions that safeguard both people and equipment. We design and manufacture high-performance air filters that meet the demanding requirements of a wide range of industries, from automotive and heavy equipment to industrial facilities, cleanrooms, and HVAC systems.

MCR inventories a large stock of Cleanroom Fan Powered and Ducted Air Filters. The Mac 10 FFU is known for being the quietest filter available and has been tested below 5O dBA with a rated flow of 90 FPM. Its modular design fits conveniently into 2`x4` to 2x2 T-Bar drop ceilings, and with a low profile of less than 13" it permits installation into tight ceiling spaces. Contact our company today!

More Foam Filter Manufacturers

Comprehensive Guide to Foam Filters: Applications, Advantages, and Selection Criteria

Foam filters have become an essential component across a wide spectrum of industries due to their superior filtration efficiency, versatility, and cost-effectiveness. Whether you are seeking high-performance air filtration solutions for automotive intake systems, industrial dust control, or even HVAC systems in commercial and residential buildings, understanding the unique properties and benefits of foam filters can help you make better, more informed purchasing decisions.

Introduction to Foam Filters

Foam filters are fabricated from open-cell polyurethane or other synthetic materials designed to trap particles while allowing air or liquid flow. Their highly porous structure makes them exceptionally efficient at removing contaminants from air, gas, or liquid streams. Foam filters are widely recognized for their high dirt retention, reusability, and adaptability to various environments, including harsh industrial settings, automotive engines, and sensitive electronic or cleanroom applications.

Key Applications of Foam Filters

- Automotive Air Filtration: Foam filters are extensively used in automobile intake systems to prevent the entry of dust, dirt, and debris into engines. Their high dirt-holding capacity makes them ideal for competitive motorsports, off-roading, and trucks operating in dusty environments.

- Exhaust and Emission Filtration: Compared to traditional paper filters, foam filters tend to have a much higher dirt retention level, making them ideal exhaust filters for vehicles and machinery. They help capture harmful particulates before they enter the atmosphere.

- HVAC Systems: In building ventilation, air conditioning, and fan coil units, foam filters are widely used for their ability to trap airborne contaminants while maintaining optimum airflow. Their low maintenance and washability make them popular in commercial and residential HVAC filter equipment.

- Industrial Equipment: Internal combustion engines, compressors, turbines, generators, and other industrial machinery frequently utilize foam filters to protect sensitive components from abrasive particulates and extend equipment lifespan.

- Specialized Environments: Foam filters are used in man-made environments requiring high purity, such as satellites, clean rooms, laboratories, and even space shuttles, due to their customizable porosity and resistance to harsh chemicals.

- Liquid Filtration: Foam is sometimes used to filter oils, water, or other liquids. Its porosity can be engineered for specific flow rates and particle capture, making it valuable in aquariums, hydroponics, and chemical processing.

How Do Foam Filters Work?

Foam filters operate on the principle of mechanical filtration. As air or liquid passes through the foam, particulate matter is physically trapped within the interconnected pores. The efficiency of a foam filter depends largely on the pore size (porosity) and the thickness of the filter material. Open-cell foam allows for excellent airflow with minimal restriction, while fine-pore foam provides higher levels of particulate capture and filtration performance—making it suitable for sensitive applications.

Retentive Additives and Enhanced Filtration Performance

To further improve filtration efficiency, a retentive additive can be combined with the foam material. These additives increase the material’s ability to capture finer particles without significantly impeding airflow or fluid movement. This approach is commonly found in performance air filters and high-efficiency industrial filtration products.

Advantages of Foam Filters Over Other Filter Materials

When selecting a filter solution, it is important to understand the unique benefits of foam filters compared to alternatives like paper filters, carbon filters, or plastic mesh filters. Here are some of the key advantages:

- High Dirt Retention: Foam filters can trap and hold much larger volumes of contaminants, reducing the frequency of filter changes and extending service intervals.

- Washability and Reusability: Many types of foam filters are washable and can be reused multiple times without significant degradation, making them more cost-effective over the long term.

- Customizable Porosity: Foam can be manufactured in a wide range of pore sizes, from coarse to fine, to match specific filtration requirements—whether you need high airflow or maximum particulate capture.

- Durability and Low Maintenance: Foam materials are typically lightweight, durable, and resistant to damage from handling or cleaning, resulting in lower maintenance costs.

- Non-Allergenic and Non-Toxic: High-quality foam filters are fabricated to be non-allergenic, non-toxic, and safe for use in sensitive environments such as hospitals, laboratories, and food processing facilities.

- Resistance to Moisture and Chemicals: Certain foam filter types are water-resistant or non-absorbent, allowing liquids to pass through without clogging or blocking the filter. This makes them ideal for applications involving moisture, oils, or aggressive cleaning solvents.

- Lightweight and Flexible: Foam filters can be easily cut, shaped, or molded to fit custom filter housings or non-standard geometries, offering design flexibility for unique filtration challenges.

Buyer’s Guide: How to Choose the Right Foam Filter

Are you researching which foam filter is best for your application? Here are the most important decision factors to consider when evaluating foam filter solutions:

- Porosity and Pore Size: Consider the size and type of particles you need to capture. Coarse foam is suitable for pre-filtration or large debris, while fine-pore foam is necessary for high-efficiency filtration and cleanroom environments.

- Airflow Requirements: Determine the necessary airflow or fluid flow rates for your system. Some applications require minimal air restriction, while others prioritize maximum filtration.

- Chemical and Moisture Resistance: For environments with exposure to oils, solvents, or water, select a foam filter with suitable resistance to these substances.

- Washability and Reusability: If reduced maintenance and long-term cost savings are priorities, choose washable foam filters that can withstand repeated cleaning cycles.

- Shape and Customization: Assess whether your application requires a custom-shaped filter, special thickness, or unique dimensions. Many suppliers offer custom foam filter fabrication to meet exact specifications.

- Operating Temperature Range: Ensure the foam filter material will perform reliably at the temperatures encountered in your application, particularly for automotive, industrial, or high-heat environments.

- Certification and Compliance: In regulated industries (such as food processing, pharmaceuticals, or aerospace), confirm that the foam filter meets all applicable safety, purity, and environmental standards.

- Cost-Effectiveness: Compare up-front costs with long-term maintenance and replacement expenses to find the best value for your specific use case.

Frequently Asked Questions About Foam Filters

- What are the main differences between foam filters and paper filters? Foam filters generally offer higher dirt retention, longer lifespan, and reusability, while paper filters are more disposable and may require more frequent replacement.

- Can foam filters be cleaned and reused? Yes, most foam filters can be washed and reused multiple times, provided they are cleaned using suitable solvents and allowed to dry thoroughly before reinsertion.

- What are the best cleaning methods for foam air filters? Use mild detergent or a specialized filter cleaner. Gently rinse and avoid damaging the foam’s structure. Some filters can be lightly oiled after cleaning to enhance dust capture.

- How do I know when to replace my foam filter? Replace the filter if it is physically damaged, degraded, or if cleaning no longer restores airflow. For critical applications, follow manufacturer maintenance schedules.

- Which industries benefit most from foam filters? Automotive, HVAC, industrial manufacturing, food processing, pharmaceuticals, laboratories, aquaculture, and motorsports are among the leading sectors utilizing foam filter solutions.

Deep Dive: Industry-Specific Use Cases for Foam Filters

Automotive and Motorsports

Foam filters are a popular choice in the automotive industry, especially for high-performance cars, motorcycles, and off-road vehicles where air quality is critical for engine longevity and power output. In racing and rallying, foam air filters provide superior filtration against fine dust and debris, reducing engine wear and supporting optimal performance. Many performance vehicle owners seek out custom foam air filters for aftermarket upgrades, drawn by their proven effectiveness and ease of maintenance.

HVAC and Building Ventilation

For commercial and residential heating, ventilation, and air conditioning systems, foam filters help maintain clean indoor air by removing pollen, dust, mold spores, and other allergens. Their washability and low pressure drop make them a sustainable and energy-efficient option for property managers and facilities operators seeking to improve air quality while minimizing operational costs.

Industrial Equipment and Manufacturing

Manufacturing environments with heavy dust, metal shavings, or chemical vapors benefit greatly from foam filters. They protect sensitive machinery—such as compressors, turbines, and CNC equipment—from abrasive contaminants, extending equipment life and minimizing downtime. Foam filters can also be used as pre-filters in multi-stage filtration systems, capturing larger particles and preserving the efficiency of downstream HEPA or carbon filters.

Laboratory, Medical, and Cleanroom Applications

In controlled environments such as laboratories, hospitals, and cleanrooms, foam filters support stringent air purity requirements. Their customizable porosity enables them to serve as pre-filters or secondary filters in air purification systems, ensuring that sensitive processes and instruments remain free from contamination.

Aquaculture, Hydroponics, and Water Treatment

Foam filters are increasingly used in aquariums, fish farms, and hydroponic systems to trap suspended solids and improve water clarity. Their non-toxicity and resistance to biofouling make them safe for aquatic life and easy to maintain.

Comparing Foam Filters With Other Filter Types

| Filter Type | Advantages | Limitations | Common Applications |

|---|---|---|---|

| Foam Filters | High dirt retention, washable and reusable, customizable porosity, durable, resistant to moisture and chemicals | May require occasional cleaning, not always suitable for ultrafine filtration (unless multi-stage) | Automotive, HVAC, industrial, aquaculture, medical, motorsports |

| Paper Filters | Low cost, easy to replace, good for single-use applications | Short lifespan, not washable, lower dirt retention | Automotive, small appliances, HVAC |

| Carbon Filters | Effective at removing odors and gases, chemical adsorption | Limited particulate filtration, can become saturated quickly | Air purifiers, industrial exhaust, HVAC, water treatment |

| Plastic Mesh Filters | Low cost, basic filtration, reusable | Low filtration efficiency, not suitable for fine particles | Pre-filters, HVAC, industrial equipment |

Optimizing Your Filtration System: Installation and Maintenance Tips

Proper installation and routine maintenance are essential for maximizing foam filter performance and longevity. Here are some expert tips:

- Ensure Proper Fit: The filter should fit snugly in its housing to prevent bypass and leakage.

- Follow Cleaning Guidelines: Always use recommended cleaning agents and procedures to avoid damaging the foam’s structure and filtration ability.

- Inspect Regularly: Periodically check the filter for clogging, tears, or degradation and clean or replace as necessary to maintain optimal performance.

- Monitor Airflow: Measure and compare system airflow before and after cleaning to verify restoration of filter efficiency.

- Lubricate if Required: Some foam filters require light oiling to enhance dust capture—refer to manufacturer recommendations.

- Document Maintenance: Keep maintenance logs for critical systems to ensure compliance and prevent unplanned downtime.

Ready to Upgrade Your Filtration System?

If you are considering switching to foam filters for your vehicle, HVAC system, or industrial equipment, explore reputable foam filter manufacturers and suppliers. For more information about specialized exhaust filters, visit our exhaust filter resource page.

Still Have Questions?

- What is the expected lifespan of a foam filter in my application?

- Can I order custom shapes or sizes for unique equipment?

- How do foam filters compare in cost and performance to HEPA or electrostatic filters?

- Are there foam filter solutions certified for food-grade or medical use?

- What maintenance schedule should I follow for maximum efficiency?

Contact leading suppliers and filtration experts to request a quote or consultation tailored to your needs.

Conclusion: Why Choose Foam Filters?

Foam filters represent a highly effective, versatile, and sustainable solution for a broad array of filtration challenges. Their superior dirt retention, washability, customizable porosity, and adaptability to harsh environments make them a smart investment for both routine and demanding applications. Whether you are responsible for industrial machinery, automotive performance, HVAC maintenance, or water treatment, foam filter technology delivers reliable results and long-term value.

For more detailed guidance, product comparisons, or to connect with trusted manufacturers, visit our air filter resources page and discover how foam filters can protect your equipment and environment.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services