Air cleaner filters are integral to the proper function of each of these tools as they can be easily clogged and accrue significant damage if the air pushed through them is not first purified to some extent. By removing water, oil, dust, vapors and other contaminants from a compressed air supply, inline filters prolong the useful life of the compressor and its applications. Read More…

Duraflow Industries is the premier aftermarket and OEM supplier of various filtration products. We feature a complete line of filters for applications such as air scrubbers, absorption of thousands of organic compounds, drinking water filtration, and waste water abatement. Our just-in-time production techniques allow us to maintain production flexibility and meet fast turnaround times. From...

For more than 25 years, RoboVent's focus has been on the delivery of clean air and healthy environments in manufacturing facilities. This has earned us the leading position in the collection and filtering of airborne contaminants generated by metalworking and other industrial processes. We are passionate about providing clean air solutions to the industry, and this dedication to the cause brings...

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Hengst Air Filtration, we are driven by a passion for clean air and advanced filtration solutions that safeguard both people and equipment. We design and manufacture high-performance air filters that meet the demanding requirements of a wide range of industries, from automotive and heavy equipment to industrial facilities, cleanrooms, and HVAC systems.

MCR inventories a large stock of Cleanroom Fan Powered and Ducted Air Filters. The Mac 10 FFU is known for being the quietest filter available and has been tested below 5O dBA with a rated flow of 90 FPM. Its modular design fits conveniently into 2`x4` to 2x2 T-Bar drop ceilings, and with a low profile of less than 13" it permits installation into tight ceiling spaces. Contact our company today!

More Air Compressor Filter Manufacturers

There are many aspects to consider when selecting an air compressor filter. Inner and outer diameter, porosity, height, maximum flow, surface area and percent efficiency are just some of the variable aspects of these filters that have significant impact on the functionality of the machine. While some filters remove general air impurities, others can reduce even vapors to less than 1ppm.

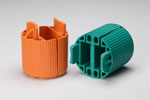

Fine filters with low porosity often require pre-filters to remove larger particulates as they will otherwise become easily clogged. These cylindrical filters may be disposable or reusable depending on the type and purpose.

Each type of air compressor has different filtration requirements, the three main types are reciprocating, rotary screw and centrifugal. The rotary screw variety, for example, is designed for near continuous use and must therefore have fresh filters more often than reciprocating compressors that are used only intermittently. Although the air compressors themselves may vary, filters all have a similar design.

The cylindrical body of the unit is actually composed of curved filter panels made of fibrous materials that catch particulates and other impurities. An end or filter cap is placed at the top and bottom of the filter panel. These are often made of stainless steel or composite plastics as they are not frequently replaced and must therefore have the durability to last through several panel changes.

An air inlet and filter discharge may be found at either the same or opposing ends of the exhaust filter depending on how the air is moved through the unit. Depending on the filtration needs of a particular compressor application, filter materials include, but are not limited to, acrylic, aluminum wire screen, electrostatic fabric, fiberglass, paper, polyester, cotton or any combination. Each of these materials allows air, but not particulates to pass into the compressor.

Selection is important as many applications, such as food processing and semi-conductor manufacturing tolerate extremely low contamination of any kind. Additional features include service life indicators, pressure gauge or integral lubricators, all of which serve to monitor and increase product longevity.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services